Technology Center

Difference between resistive touch screen and capacitive touch screen

With the rapid development of touch screen technology, there are many common types of touch screens on the market, including resistive touch screens, capacitive touch screens, infrared touch screens, surface acoustic touch screens, and so on. Although new touchscreens are constantly emerging, capacitive and resistive touchscreens dominate today's market.

If you are considering choosing a suitable touchscreen for your project, which of these two is better? To answer this question, you can read this article on the differences between capacitive and resistive touchscreens. From there, choose the touchscreen option that best meets your needs based on your application.

What is a capacitive touch screen?

A capacitive touch screen is a common touch screen technology. It consists of a transparent conductive layer, inductive electrodes, and control circuits and is widely used in panel PCs, automobile navigation systems, and industrial control. Unlike resistive touch screens, which utilize the principle of applying pressure, capacitive touch screens utilize the natural conductivity of the human body. Since the human body is a conductor, touching the screen's surface with a finger will interfere with the screen's electrostatic field, thus sending its position to the controller for processing.

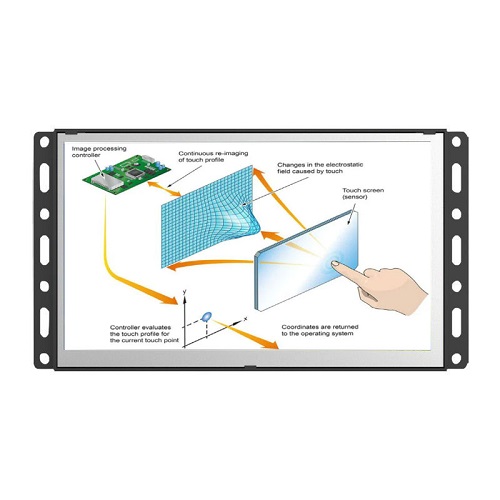

How does capacitive touch screen work?

The principle of a capacitive touch screen is to work through the human body's current sensing. When the finger touches the metal layer, a coupling capacitor is formed between user and the touch screen surface due to the electric filed of the human body. The capacitor is a direct conductor for high-frequency current, so the finger draws a small current from the contact point. The current flows from the electrodes at the four corners of the touch screen, and the current flowing through these four electrodes is proportional to the current flow of the user. The controller calculates the exact ratio of these four currents to obtain the position of the touch point.

Advantages of capacitive touch screens

Multi-touch support

Capacitive touch screens allow for multi-touch, meaning people can pinch or zoom on the touch screen, recognizing the touch input of multiple fingers and providing a richer operational functionality and interactive experience.

Fast Response

Capacitive touchscreens have a fast touch response speed that immediately captures user input and provides a smooth operating experience.

Scratch and Wear Resistant

Capacitive touch panels are made of wear-resistant glass or plastic materials with high scratch and abrasion resistance, which can maintain the clarity of the screen and touch accuracy for a long time. If the capacitive touch screen is cracked, it can continue to operate. Resistive touch screens usually stop working when their surface is damaged.

High Transparency

Capacitive touch screens have high transparency and contrast and do not require an additional touch input device, so users can easily view what is displayed.

Disadvantages of capacitive touch screens

However, there are some disadvantages of capacitive touch screens:

Affected by the environment

Capacitive touch screens can be disturbed in extreme temperatures, humidity, or dusty environments, resulting in inaccurate touch positioning or misuse.

Inability to Recognize Non-Conductive Objects

Capacitive touch screens can only recognize conductive objects such as fingers, capacitive stylus, etc. They cannot recognize non-conductive objects such as gloves or plastic pens.

Higher cost

Capacitive touchscreens cost more than other touch technologies, which can increase the overall price of the product.

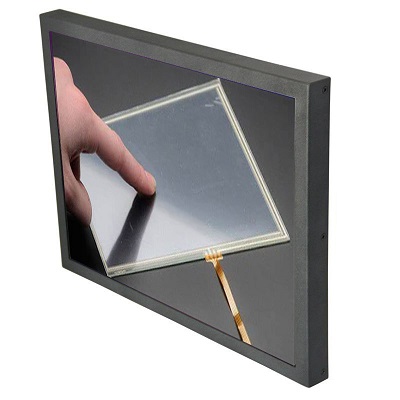

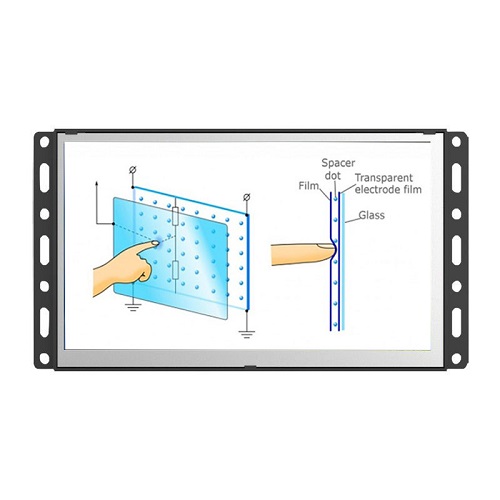

What is a resistive touch screen?

Resistive touch screen is the older traditional touch screen technology. A resistive touch screen consists of two layers of conductive film, a top layer and a bottom layer. When the user presses a finger or other object against the screen, the top layer of film bends and comes into contact with the bottom layer, and the resistance between the top and bottom layers changes, generating an electric current. These are then sent to the controller, which determines the touch's position by the current change.

How does resistive touch screen work?

A resistive touch screen operates and controls the contents of the screen mainly through the principle of pressure sensing. The body of a resistive touch screen is a multilayer composite film that fits the surface of the display very well. The upper and lower layers are coated with a transparent conductive substance, which creates resistance when you touch the screen and press it, thus generating an electric current. The controller reads out the corresponding current and calculates the distance of the finger position from the four angles by measuring the change in current.

Advantages of resistive touch screens

Adaptable

In simple terms, resistive touchscreen technology is that it relies on physical pressure. So any issue that applies force to the screen can achieve the same effect. Resistive touchscreens can be touched using fingers, gloves, stylus, and other objects.

Strong anti-interference ability

Since a resistive touch screen needs to apply some pressure to trigger, its relative anti-interference ability is strong, and it has good anti-interference ability for some accidental touch or accidental touch of objects. In addition, even if there is liquid or debris on the surface of the touch screens, they can maintain normal operation. As a result, resistive touch screens are ideal for agricultural equipment and underwater machinery.

Low cost

Cost is also a very important factor to consider when choosing a touchscreen. Resistive touch screens are generally more affordable than other types of touch screens. Therefore, the price advantage of resistive touch screens is one of the reasons why they are widely used.

Disadvantages of resistive touch screens

Single-touch

Resistive touch screens are usually only capable of single-touch, not multi-touch. So if there are multiple inputs such as zooming or pinching, a resistive touch screen cannot determine the touch's location.

Low Visibility

The thin-film substrate at the top of a resistive touchscreen reduces the display's light transmission, affecting the screen's brightness and clarity.

Susceptible to damage

Since resistive touch screens rely on the principle of mutual contact between film substrates to work, the film substrate will wear out over time. Then it requires to be recalibrated or replaced at a certain time.

Capacitive vs resistive touch screen: what are the differences?

After learning how capacitive and resistive touchscreens work and the advantages and disadvantages of each, you should already have a general understanding of the differences between the two. Below you will find an overview of the key differences and help you make an informed choice for your project.

User experience and sensitivity

l Capacitive touch screens offer a better user experience, as they can realize multi-touch and support gesture operation, providing richer interactive functions and a natural operating experience. In addition, capacitive touch screens are also very responsive and sensitive to touch.

l Resistive touch screens have a lower sensitivity and require more pressure to trigger. They can only realize single touch, and the user experience is relatively limited. However, resistive touch screens can be touched using any object.

Accuracy and precision

l Capacitive touch screens have higher touch accuracy and precision than resistive screens. They enable finer touch positioning and operation and recognizes smaller objects, allowing users to perform more precise operations.

l Resistive touch screens have lower accuracy and precision than capacitive touch screens. Due to pressure-triggering characteristics, the touch area may have some positioning errors and ambiguity.

Suitability for different applications and industries

l Capacitive touch screens are widely used in panel PCs, car navigation, and industrial control. Capacitive touchscreens suit high touch sensitivity and multi-touch scenarios to provide a richer user interaction experience.

l Resistive touch screens are used in agricultural equipment, medical equipment, underwater equipment, or applications requiring gloves. They are suitable for environments that require scratch and abrasion resistance, anti-interference, and adaptation to the touch of different objects.

Operating environment

l Capacitive touch screens are relatively weak regarding environmental resistance and durability. They are sensitive to extreme temperature, humidity, electric field, dust, and other environmental conditions, which may affect the touch accuracy and reliability.

l Resistive touch screens are not easily infected by dust, water vapor, and oil. They can adapt to various environmental conditions, such as high temperature, low temperature, and humidity. The resistive touchscreen has more robust structure, is scratch and wear-resistant, and can operate stably for a long time in harsher industrial environments.

Service life

l Capacitive touch technology utilizes current sensing, which is less abrasive to the screen and has a long service life.

l Resistive touch technology uses pressure sensing, which is easy to wear the screen leading to damage to the touch function and short service life.

Cost

l Capacitive touch screens are more costly than resistive touch screens due to their complex structure and high technical requirements. This is because capacitive touch screens require special materials and manufacturing processes to achieve multi-touch and high sensitivity.

l Resistive touchscreens have a relatively simple and low-cost manufacturing process. This makes it more competitive in some cost-sensitive applications.

Conclusion

When choosing which touchscreen technology to use, it is important to consider the specific application scenario and requirements. Advanvision can help you determine which touchscreen technology to use based on your project's unique needs. Advanvision's touchscreens for industrial monitorsand industrial panel PCs support both resistive and capacitive touch options, so no matter what type of touchscreen your product requires, Advanvision can help. According to your type of touchscreen your product requires, Advanvision has an effective solution for your application. If you would like to learn more information, we are happy to assist you at any time.

RELATED NEWS

- Why does the ordinary LCD screen display poorly in the sunlight? 2023-01-28

- What are the differences between the industrial panel PCs and commercial all-in- 2022-11-21

- Design principles and benefits of fanless industrial Touch Panel PCs 2022-09-27

- Application and function of AG, AR, AF cover glass in industrial monitor and Pan 2022-09-27

- Waterproof Grades of Stainless Steel Touch Panel PCs – IP65, IP67, IP68, and IP6 2025-06-18

CATEGORIES

LATEST NEWS

CONTACT US

Contact: John (Business manager)

Phone: 0086-13267019667

E-mail: sales@advanvision.com

Add: B2, Mingjun industrial park, Dalang, Longhua District, Shenzhen, China