Technology Center

Overview of optical binding(GFF) technology for LCD displays

What Is Optical Bonding For LCD Displays?

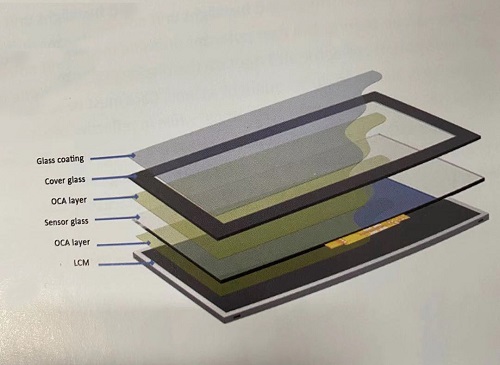

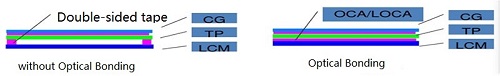

Optical bonding for LCD (Liquid Crystal Display) displays is a technique used to enhance the optical performance and durability of the display by reducing the air gap between the LCD panel and the outer protective layer, usually a piece of glass or other transparent material. This process involves applying a special optical adhesive between the LCD panel and the protective layer, effectively "bonding" them together. Optical bonding is commonly used in industrial applications, outdoor displays, digital signage, ruggedized devices, and any situation where improved visibility, durability, and performance are crucial.

Steps Of Optical Binding

l Preparation: The LCD panel and the protective layer (usually glass) are thoroughly cleaned to remove any dust, dirt, or contaminants that could affect the bonding process.

l Application of Adhesive: A specialized optical adhesive is applied to either the LCD panel or the protective layer. This adhesive is chosen for its optical clarity, thermal stability, and compatibility with the LCD technology.

l Bonding: The LCD panel and the protective layer are carefully aligned and pressed together to eliminate the air gap between them. The adhesive spreads evenly to ensure a uniform bond.

l Curing: The adhesive is cured or hardened using heat, ultraviolet (UV) light, or other methods. This step ensures a strong and durable bond between the LCD panel and the protective layer.

The Main Advantages Of Optical Bonding

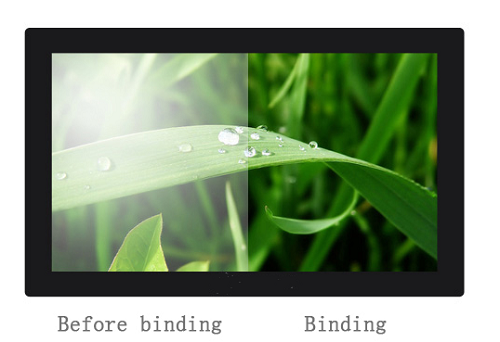

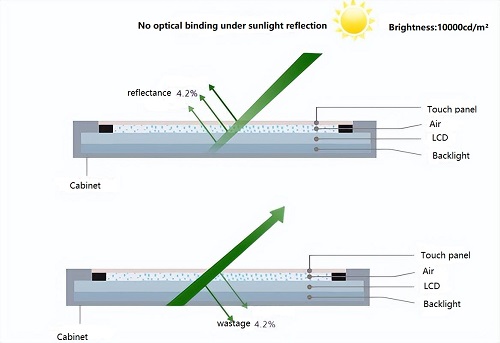

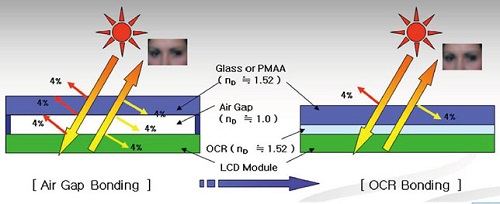

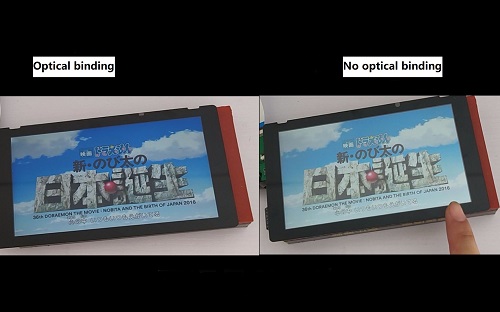

l Reduced Reflections and Glare: Optical bonding eliminates the air gap between the LCD panel and the protective layer (usually glass), reducing the number of interfaces where light can be reflected. This results in reduced glare and improved visibility, making the display easier to read in bright environments.

l Enhanced Outdoor Visibility: LCD displays used outdoors are often subject to increased ambient light, which can cause reflections and make the screen difficult to read. Optical bonding improves outdoor visibility by reducing the impact of reflections and increasing contrast.

l Improved Image Clarity: With reduced reflections and better light transmission, optical bonding can enhance the perceived image quality and sharpness of the display. This is particularly important for applications where fine details and text need to be clearly visible.

l Durability and Impact Resistance: The bonding process creates a protective layer over the LCD panel, making it more resistant to physical impacts, scratches, and other forms of damage. This is essential for applications in rugged environments or high-traffic areas.

l Moisture and Dust Resistance: The tight seal created during optical bonding helps prevent moisture, dust, and other contaminants from infiltrating the display. This is especially important in environments where the display may be exposed to these elements.

l Touchscreen Accuracy: For displays with touch functionality, optical bonding can improve the accuracy and responsiveness of touch interactions. The elimination of the air gap between the display and the touch sensor enhances touch sensitivity.

l Seamless Aesthetics: In applications requiring multiple LCD panels to be combined into a larger display, optical bonding creates a seamless appearance by eliminating the visible borders between the panels.

l Vandal Resistance: Bonding enhances the display's resistance to vandalism and tampering, as it adds an additional layer of protection.

l Longer Lifespan: By protecting the LCD panel from external factors such as moisture, dust, and physical damage, optical bonding can contribute to extending the display's operational lifespan.

Which Applications Need To Use Optical Binding Technology?

l Outdoor Displays: LCD displays used in outdoor environments face challenges such as increased glare, reflections, and exposure to harsh weather conditions. Optical bonding helps mitigate these issues by reducing reflections and enhancing visibility, making the display more readable in bright sunlight.,

l Ruggedized Devices: Devices intended for industrial or outdoor use, such as rugged tablets, industrial control panels, and military equipment, benefit from optical bonding to increase durability and resistance to impacts and environmental stressors.

l Digital Signage: Large-scale digital signage displays are often used in public areas, transportation hubs, retail environments, and other locations where aesthetics and visibility are crucial. Optical bonding minimizes reflections and provides a seamless appearance across multiple display modules.

l Interactive Kiosks: Touchscreen kiosks used in public spaces, museums, information centers, and commercial settings require precise touch accuracy and reduced reflections to provide an optimal user experience. Optical bonding enhances both touch responsiveness and visibility.

l Medical Devices: LCD displays used in medical equipment, such as diagnostic devices, surgical displays, and patient monitoring systems, benefit from optical bonding by providing improved clarity and touch accuracy for healthcare professionals.

l Aviation and Automotive Displays: Cockpit displays in airplanes and instrument clusters in vehicles require high visibility under varying lighting conditions. Optical bonding enhances the readability of these displays by reducing glare and reflections.

l Marine and Maritime Applications: Displays used in marine environments, such as navigation systems, sonar displays, and shipboard control panels, benefit from optical bonding's ability to withstand moisture, saltwater exposure, and harsh weather.

l Gaming Machines: Arcade games, slot machines, and other gaming devices often use touchscreens for interaction. Optical bonding enhances touch response and ensures clear visibility, enhancing the gaming experience.

l Aerospace and Space Applications: Spacecraft instrumentation, satellite displays, and equipment in aerospace applications require robust displays that can withstand space environments and maintain optimal visibility.

RELATED NEWS

- Why does the ordinary LCD screen display poorly in the sunlight? 2023-01-28

- What are the differences between the industrial panel PCs and commercial all-in- 2022-11-21

- Design principles and benefits of fanless industrial Touch Panel PCs 2022-09-27

- Application and function of AG, AR, AF cover glass in industrial monitor and Pan 2022-09-27

- Waterproof Grades of Stainless Steel Touch Panel PCs – IP65, IP67, IP68, and IP6 2025-06-18

CATEGORIES

LATEST NEWS

CONTACT US

Contact: John (Business manager)

Phone: 0086-13267019667

E-mail: sales@advanvision.com

Add: B2, Mingjun industrial park, Dalang, Longhua District, Shenzhen, China